Over 6000 man-hours saved in Adani RMRW brownfield project

Companies worldwide trust Bidaal to enhance workplace safety and empower their workforce. Learn how our AI-driven solutions proactively protect employees and improve operational efficiency.

Identify Areas Of Risk With Scaling Workforce

Mundra, located in the Kachchh district of Gujarat is hub to Adani’s multiple projects, be it Adani Thermal Power Plant, Adani Ports, or Adani Solar Projects. While these projects have been in operation for some time, there have been continuous infrastructural updates for increasing productivity and operational efficiency. In 2024, Adani Thermal Power Plant decided to add to the list of their already existing MLD Desalination plant for supplying desalinized water for their production. However, the scale and intensity of these industrial-level undertakings introduced a range of operational challenges, particularly in maintaining adherence to safety protocols. Moreover, being a greenfield project, the operational challenges encountered were unique when compared to usual industrial brownfield projects.

The lack of proper fencing or defined boundaries, resulted in trespassing from civilians, and at times animals. Not only these unwanted movements raised the possibility of accidents but also resulted in theft of goods and resources. Such breaches not only contravened Adani’s Environmental, Health, and Safety (EHS) policies but also adversely impacted operational efficiency and project timelines.

In industrial construction, where projects are of elevated complexity, the dual priorities of timely completion and the maintenance of safety standards are of utmost importance. Given that automatic and semi-automatic machineries are frequently operational, unwanted man-machine interaction of any kind could have fatal consequences.

Addressing these safety lapses became imperative for ensuring sustainable growth, safeguarding worker well-being, and maintaining the momentum of infrastructure development across the Mundra Desalination plant.

"Our project required a robust system to address the numerous challenges, and with the AI-enabled CCTV cameras, we achieved the desired results. We not only achieved lesser work place violations, but also with the monitoring system in place, there was a significant reduction in theft of materials."

Smruti Ranjan PariaDy. General Manager, Adani

Identify Areas Of Risk With Scaling Workforce

To implement a robust and scalable safety solution, Adani Group collaborated with Bidaal to monitor possible safety violations and to establish a systematic approach for addressing these recurring infringements.

The primary objective was to eliminate the conventional method of manual inspection across operational areas and instead introduce a digitally automated monitoring system. The focus of this initiative was to automate the initial three of the four key steps in Adani’s safety framework — Detect, Analyze, Report, Improve — thereby maximizing efficiency and outcomes.

In traditional industrial standards safety managers relied on manual processes to uphold safety standards which posed risks such as the potential oversight of violations and significant loss of man-hours. Moreover, greenfield projects often have their unique set of violations, that requires customized solution to address the possible challenges.

To mitigate these issues, 4 surveillance cameras were deployed across construction zones within the plants to streamline and enhance the monitoring process. These cameras were integrated with Bidaal’s AI Video Analytics solution, with customized parameters to detect violations specific to Adani RMRW Mundra site.

Following a detailed assessment of operational zones and a thorough definition of potential safety violations, the AI model was trained to accurately detect such hazards. Violations were tracked through an intuitive software platform that provided 24/7 monitoring capabilities. The system also empowered users to assign specific personnel for incident reporting, with options for real-time alerts or comprehensive weekly reports offering an overarching view of safety compliance.

80% Reduction In Incidents

Following the successful deployment at Adani’s airports, similar positive results were anticipated at the Mundra region. While introducing a new and advanced set of parameters often carries the risk of inaccuracies, Bidaal’s solution performed with impressive precision.

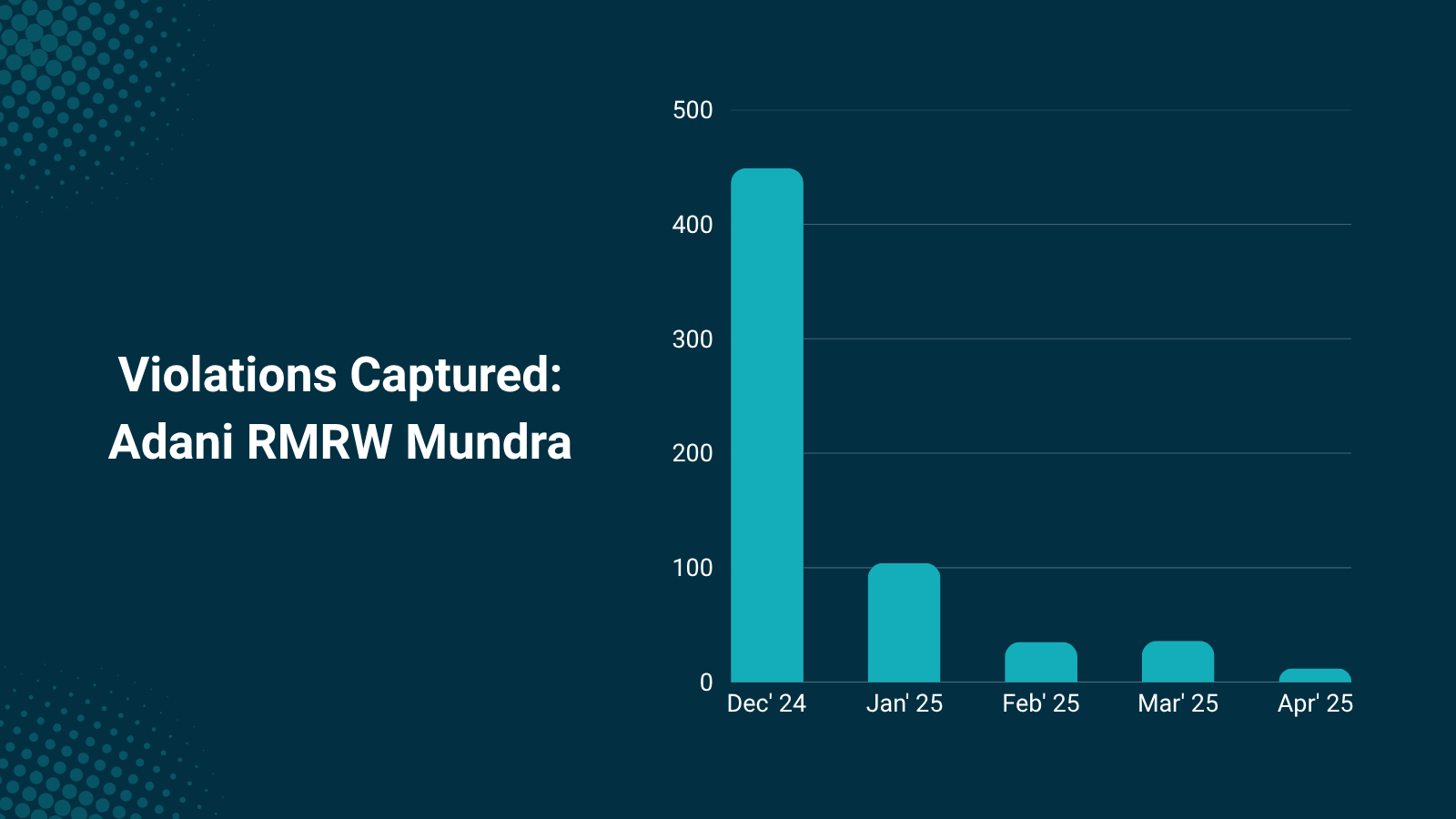

In the very first month, the system detected 453 violations under Adani RMRW’s customized categories — namely “No Access to Humans” and “No Entry Zones.” The automated detection and alerting system kept the Adani EHS team informed in real time and helped them identify key safety gaps. This led to an immediate impact: a 62% drop in violations the following month, with all remaining incidents categorized under “PPE” violations.

One of the standout features tailored for the Adani RMRW site was keeping count of vehicle movement. The system accurately monitored hundreds of vehicles entering and exiting the premises each day, enabling the EHS team to validate authorized movement and keep track of unauthorized access effectively.

As the number of violations dropped to double digits in the subsequent months, the site saw a significant improvement in operational efficiency. Not only did the operations sped up, the EHS team ended up saving crucial 6000 man hours. In addition to reducing safety-related incidents that could lead to major losses, the solution helped prevent resource theft — a long-standing issue at the Mundra site. Over the past six months, there was a significant financial saving where Bidaal’s system helped Adani RMRW save over ₹25 lakhs.

Let’s walk you through the platform