Modernize your illumination planning

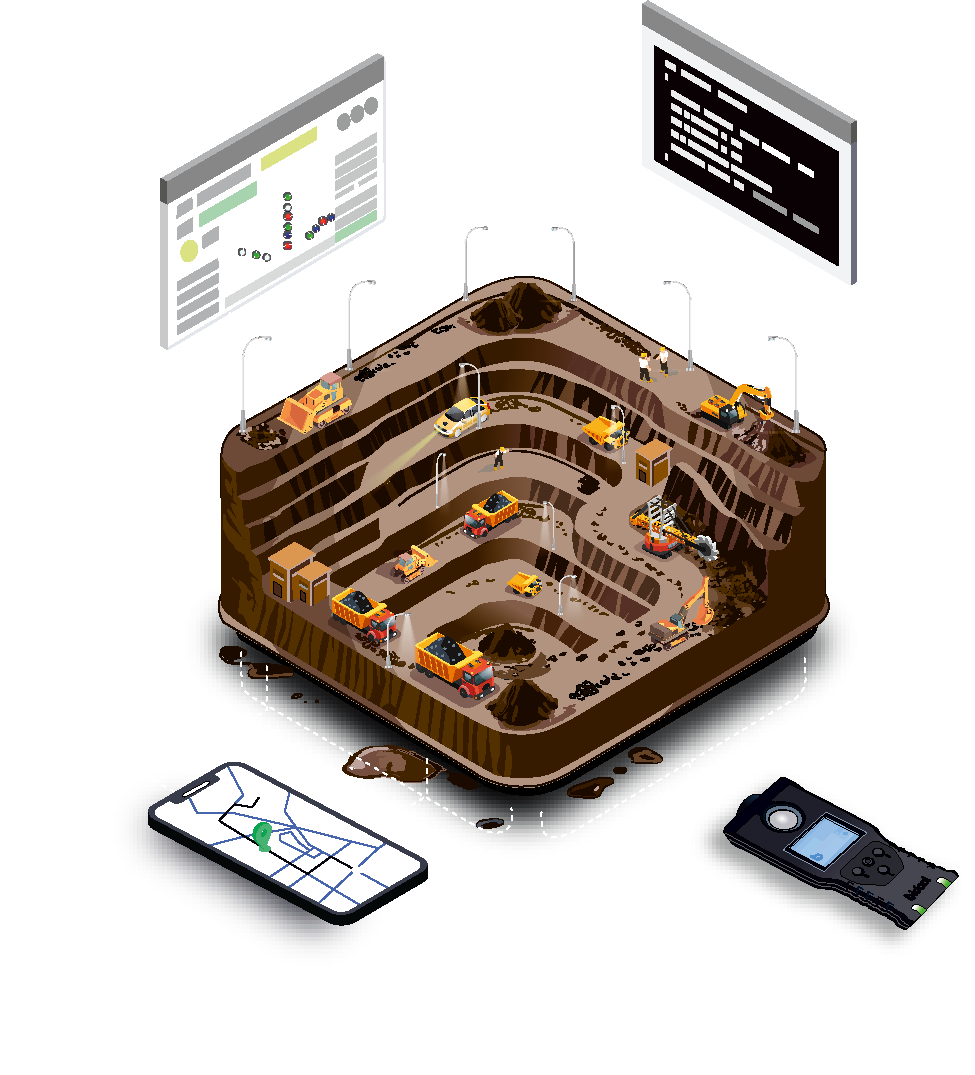

Quick Setup, Fast Surveying

Conducting surveys requires no extra effort as you only need to attach the device to the vehicle, switch it on and let the device take care of the rest.

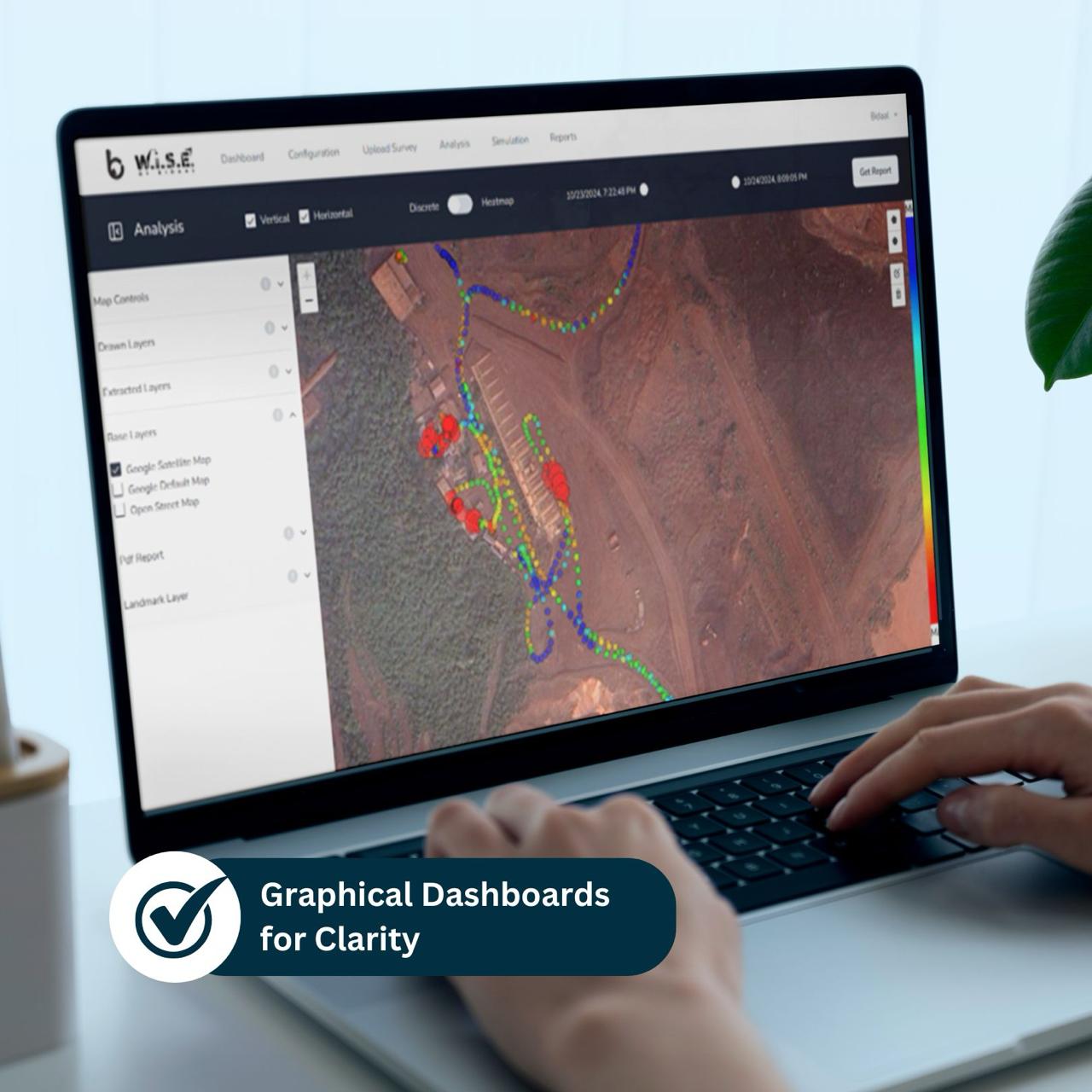

Complex Data Represented Graphically

The dashboard allows you to visualize all the illumination data points on your site map. Choose time frames, selective locations, and other features for easier understanding.

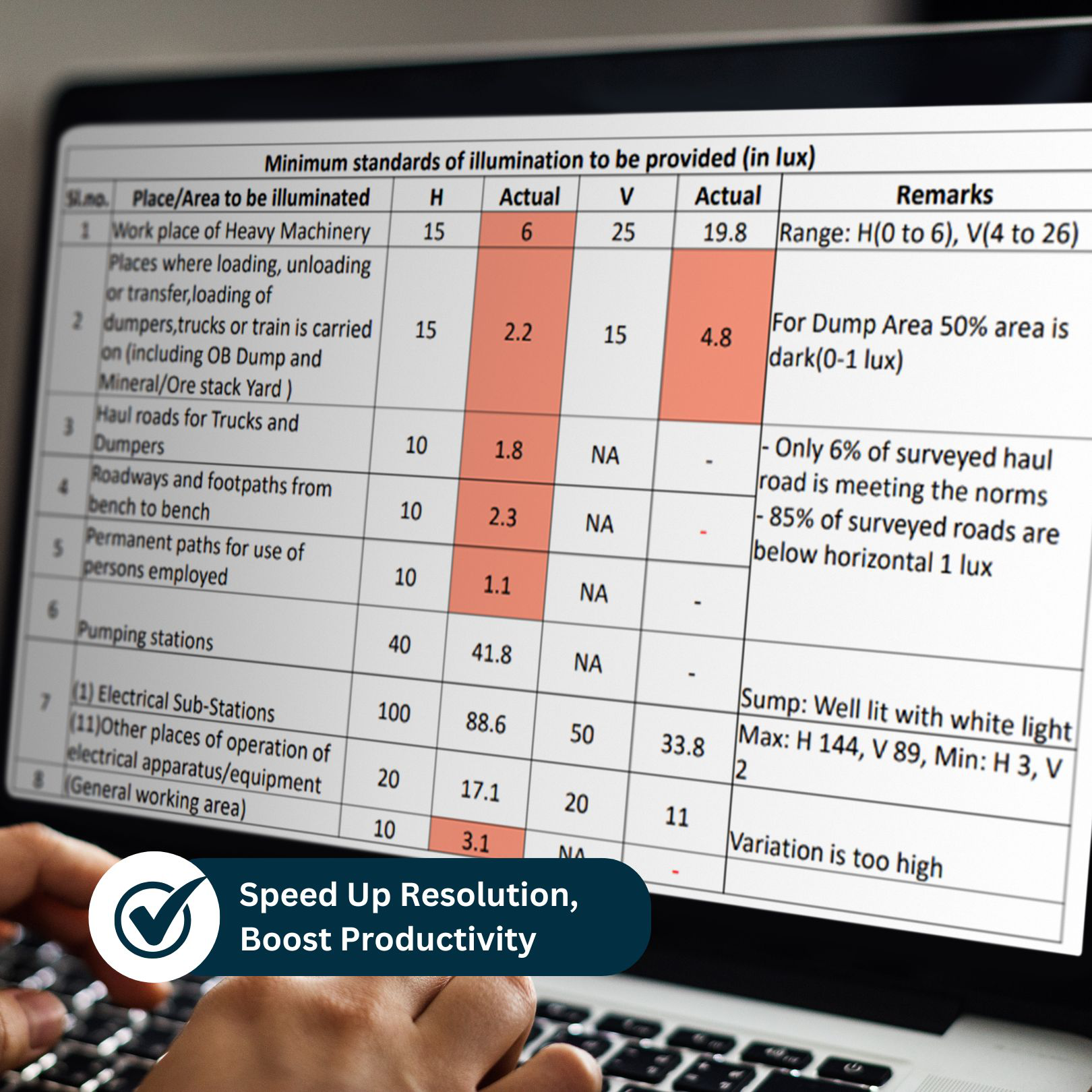

Digital Reports for Regulatory Compliance

The software allows you to generate comprehensive survey reports for maintaining regulatory standards, while also informing you about the under and over illuminated areas.

Explore the Key Attributes

Statutory Report Generation

Illumination Gap Analysis

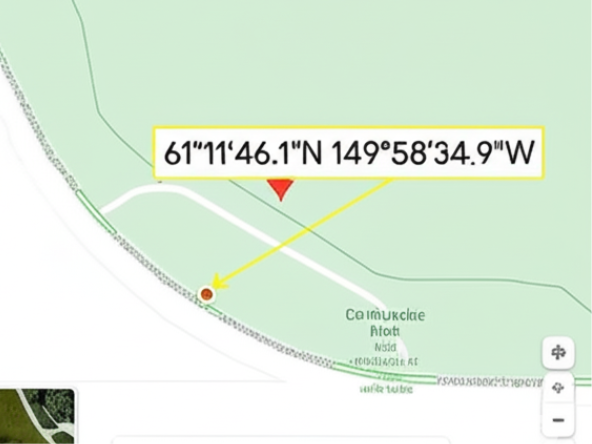

Geographical coordinate points

AI-based Illumination planning

Preferred survey method

Simplified area demarcation

Case Studies

JSW Steel achieves optimum illumination in Nuagaon Iron Ore mine

JSW Steel partnered with Bidaal, adopting its W.I.S.E system across all its Odisha-based mines, including the Nuagaon mine, to conduct periodic surveys and address illumination gaps

MCL achieves 70% improvement in overall illumination uniformity index

After internal illumination survey revealed that the existing lighting infrastructure, especially in high-traffic operational areas could be under illuminated, MCL adopts AI-backed survey methodology

TATA Steel OMQ detects over 1000 under-illuminated zones across mines

TATA Steel OMQ improves illumination standards across the iron ore mines by implementing Bidaal’s W.I.S.E system, adhering to DGMS compliance requirements and improving operational efficiency

Hear What Clients Have to Say

Use case senario

Reporting and Insights

Bidaal FAQs

What kind of hardware equipment does Bidaal provides?

Bidaal provides a range of hardware systems ranging from CCTV lens, survey device, traffic management devices, and CPUs among others depending on the projects’ needs.

Is the hardware equipment used of the highest quality?

Bidaal uses ISO 9001 certified hardware components ensuring the best possible quality for the products.

How long is the warranty of the hardware system?

We ensure that any minor defects are covered by us post-installation. But for major damages, the hardware components need to be replaced by the user.

Let’s walk you through the platform