Inoxpa achieves object-counting efficiency of 800 per minute with AI-enabled camera system

Companies worldwide trust Bidaal to enhance workplace safety and empower their workforce. Learn how our AI-driven solutions proactively protect employees and improve operational efficiency.

Identify Areas Of Risk With Scaling Workforce

Inoxpa India, subsidiary of the Spanish-based INOXPA, specializes in manufacturing stainless steel fluid handling components and equipment, management of processes and services in the food-processing, cosmetic and pharmaceutical industries. As a multinational company with global footprint, Inoxpa has a substantial production rate, creating thousands of parts on an annual basis. Given the high production rate, possibilities of failure also increased significantly, requiring Inoxpa to rely on external solutions.

In the initial stages of its operations, Inoxpa opted for a manual workforce to handle the counting of finished goods such as O-rings, valves, and similar components. This decision was largely driven by the perceived economic advantage of hiring manpower, especially for small-scale production units. However, as production volumes increased — with thousands of parts being manufactured daily — this approach began to reveal several operational inefficiencies.

One of the key challenges encountered with manual counting was the onset of sensory fatigue among workers. Tasks requiring repetitive visual focus often led to dizziness and disorientation, resulting in frequent miscounts. These errors disrupted the operational flow, leading to inventory mismatches and delays.

Additionally, while the initial cost of employing manual labor appeared economical, it became evident that this was not a financially sustainable model in the long run. Labour costs accumulated over time, and periodic wage increments further added to the recurring expenditure. From a financial management standpoint, this growing overhead raised concerns for the leadership at Inoxpa.

To address these inefficiencies and streamline the counting process, Inoxpa introduced a "counting by weight" methodology. In this system, components were grouped into packets of standardized weight. By referencing the same weight of each individual part, the team could estimate the quantity of items per packet. Minor yet impactful variations in the weight of individual components led to discrepancies in counts. These inconsistencies undermined the reliability of the weight-based system, occasionally resulting in either surplus or deficit quantities in packaging.

"Inoxpa’s need to streamline their counting process and increase their efficiency required a combination of mechanical and advanced AI-system. Bidaal’s AI-enabled cameras integrated with our counting system not only increase the object-counting efficiency but also proved highly accurate."

Saswat Kumar SahuCTO, Quro Labs

Identify Areas Of Risk With Scaling Workforce

To address the challenges faced by Inoxpa in their manual and weight-based counting methods, Bidaal joined hands with Quro Labs and deployed its proprietary Bidaal LENS technology — a sophisticated AI-driven video analytics solution designed specifically for high-accuracy part detection and counting in industrial environments.

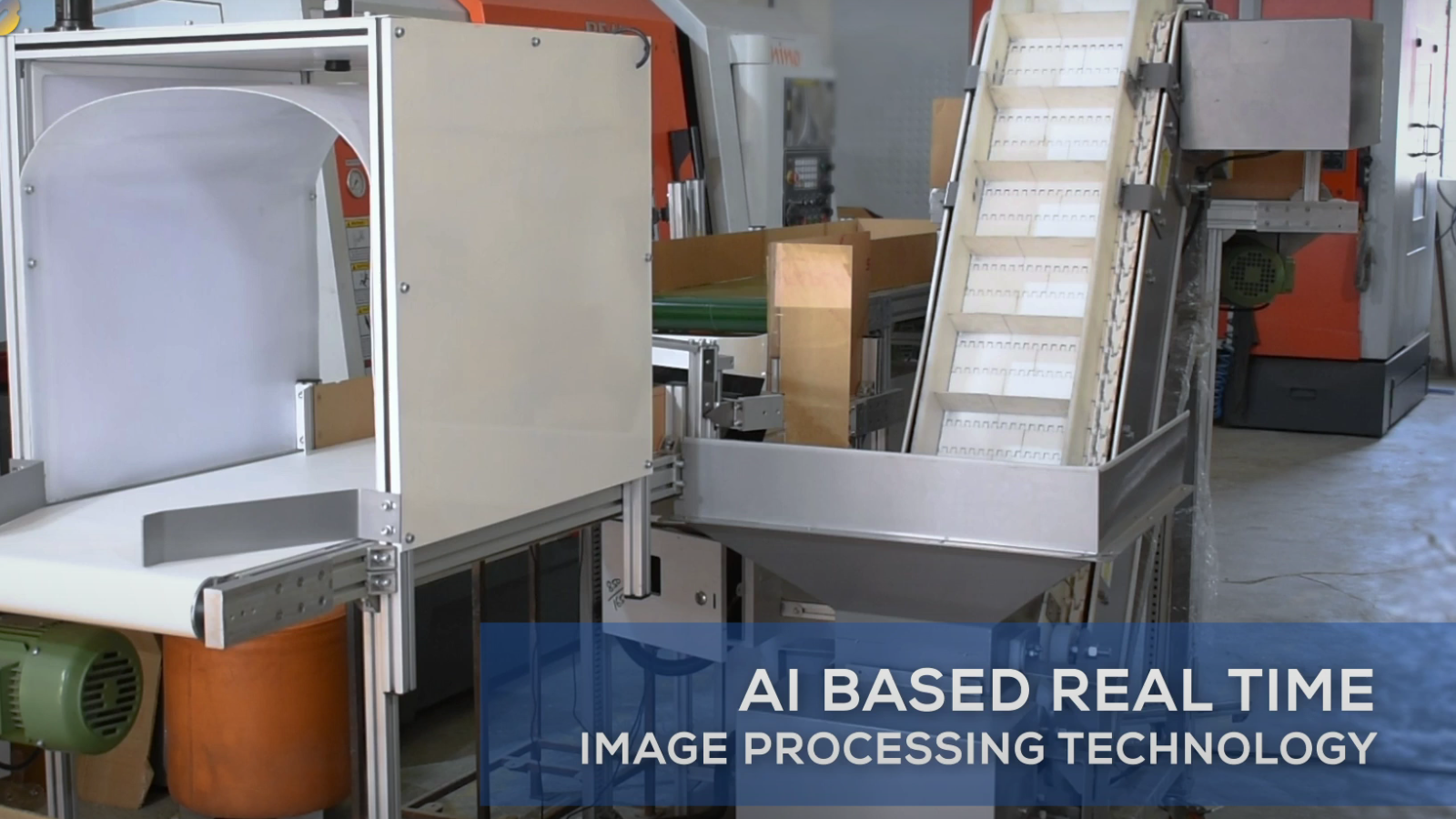

While Quro Labs designed the counting device to regulate the flow of finished products, at the front end, the system utilized a combination of strategically positioned cameras and processing units to replace human counters in real time. These cameras were installed above the conveyor belts and trained using AI algorithms to recognize and count various types of components with high precision. This setup not only eliminated human error but also enabled a significant increase in conveyor speed, thereby improving overall throughput.

On the back end, the solution incorporated intelligent software capable of tracking individual part counts, organizing batch-wise data, and maintaining time-based logs of each counting cycle. This created a complete and traceable digital record of the process, adding a layer of operational transparency and reliability.

In addition to the primary conveyor-based counting, Bidaal implemented a parallel counting technique to address a critical limitation — the miscounting caused by parts stacking over one another. The company introduced a gravity-drop method, where parts were allowed to free-fall in front of a well-lit white background. As the components dropped, a dedicated camera captured the shadows of the falling parts. This shadow-based detection method eliminated the inaccuracies caused by overlapping parts, as it relied on distinct visual separation rather than physical arrangement. As a result, counting accuracy was further improved, ensuring the system’s robustness across different part geometries and drop rates.

80% Reduction In Incidents

The implementation of Bidaal’s AI-powered solution in Quro Labs system brought measurable improvements to Inoxpa’s operations, not only refining the counting process but also contributing significantly to economic stability and growth.

One of the most notable outcomes was the substantial reduction in counting errors. By eliminating the dependency on manual counting, Inoxpa witnessed a dramatic drop in error rates. While no system is entirely error-proof, Bidaal’s technology consistently maintained an accuracy rate of up to 98%, with errors capped at a fixed 2%. In contrast, manual counting was marked by unpredictable fluctuations in accuracy, making it difficult to integrate into a standardized operational model. The consistency offered by the digital system allowed Inoxpa to align its production planning, operations, and compliance processes around this fixed margin of error, streamlining internal workflows.

From a financial perspective, the adoption of Bidaal’s solution led to a significant reduction in recurring costs. The manual approach demanded continuous investment in salaries, periodic wage increases, and recurring hiring efforts. Over time, these cumulative costs were projected to exceed the one-time capital investment required for the digital system. Furthermore, the inconsistent accuracy of manual counting posed long-term risks to inventory management and production efficiency, potentially hindering economic performance.

In terms of operational efficiency, the introduction of automation provided a considerable performance boost. Unlike human operators who limited the speed of the conveyor systems due to counting constraints, the AI-based system enabled Inoxpa to scale up operations. After a series of fine-tuned iterations, the company successfully optimized its process to achieve a counting speed of up to 800 parts per minute — a feat that would have been unachievable with human oversight alone.

Let’s walk you through the platform