With 5.5 ton/year CO2 reduction, HZL upholds its EHS standards, moving towards a greener future

Companies worldwide trust Bidaal to enhance workplace safety and empower their workforce. Learn how our AI-driven solutions proactively protect employees and improve operational efficiency.

Identify Areas Of Risk With Scaling Workforce

Traffic-related violations and accidents remain one of the most pressing challenges across India, affecting not only public roads but also industrial environments. Within industrial zones, such incidents not only pose serious risks to life and property but also impede adherence to Environmental, Social, and Governance (ESG) standards and Corporate Social Responsibility (CSR) commitments. Hindustan Zinc Limited (HZL), a subsidiary of Vedanta Limited and a global leader in zinc and silver production, was confronting similar challenges at its plant located in Jharsuguda, Odisha. A series of near-miss incidents had raised significant concern regarding lapses in safety protocol adherence and had begun to impact the efficiency of operational workflows.

Following a detailed assessment, three primary issues were identified as root causes of the safety concerns at the site. Firstly, the facility includes a convergence of three sharp 90-degree turns, creating substantial blind spots for vehicle operators. The lack of visibility at these intersections significantly increased the likelihood of near-miss events and collisions, posing risks to both personnel and infrastructure.

Secondly, non-compliance with traffic regulations by smaller vehicles emerged as a recurring issue. These vehicles frequently bypassed intersection rules, proceeding without halts, which in turn delayed the movement of heavy trucks exiting the premises with essential materials. This not only hampered logistics and operational timelines but also necessitated the deployment of on-ground traffic personnel to manually manage vehicle flow—an inefficient and unsustainable approach.

Lastly, these intersections remained continuously congested with a mix of public and industrial traffic, raising persistent safety concerns. Contributing factors such as driving on the wrong side of the road and frequent instances of overspeeding further heightened the risk of major accidents within the premises of HZL.

"Bidaal’s AI-powered powered for solution for over-speeding and wrong-path violation is excellent in performance. It ensures on-road safety while keeping records and improves tracking. This is a powerful tool to make mining industry future ready. "

Mukesh K. VyasProgram Manager, Startup & Innovation, HZL, Zinc Sector

Identify Areas Of Risk With Scaling Workforce

The reliance on manual intervention at key junctions within the Hindustan Zinc Limited (HZL) premises had resulted in extended waiting times, adversely impacting economic performance, financial output, and overall operational efficiency. To address this multifaceted issue, Bidaal introduced an innovative and advanced solution positioned at the intersection of Artificial Intelligence (AI) and the Internet of Things (IoT).

However, prior to implementation and commencement of operations, it was imperative for Bidaal to obtain a comprehensive understanding of the site's traffic dynamics, geographical layout, and prevailing on-ground regulations and compliance requirements. The distinguishing strength of Bidaal’s proprietary system, SMILE, lies in its adaptability—designed to be tailored in accordance with specific operational scenarios and thereby capable of managing diverse industrial traffic complexities.

In the case of HZL, initial configuration priorities were clearly defined. Industrial vehicles were given precedence over general vehicles and pedestrians, given the heightened risks associated with heavy-duty equipment and materials transport. A secondary layer of prioritization was determined based on key geographical and structural factors, including road gradient, proximity to critical production units, and the presence of road diversions or speed breakers.

Once the foundational logic was defined, Bidaal deployed detection units—its proprietary smart cameras—at each identified intersection. These cameras were integrated with on-site processing units and LED traffic signals. The processing units, powered by Bidaal’s patented traffic management technology, functioned as autonomous traffic controllers. They leveraged sophisticated algorithms to operate the LED lights and facilitate a coordinated and optimized flow of vehicles.

Although the system’s core functionality was to enable intelligent traffic signaling based on standard traffic flow while generating alerts for vehicular movement, the AI-enhanced system offered extended capabilities. It proactively monitored incidents of overspeeding and unauthorized turns, incorporating such violations into its signal logic to optimize safety. Furthermore, the smart cameras captured and logged details of vehicles breaching regulations, storing this data securely for potential enforcement and disciplinary actions, thereby strengthening accountability and compliance.

80% Reduction In Incidents

While the deployment and operational structure of SMILE as a service involved a high level of technological complexity, the outcomes were both straightforward and highly rewarding.

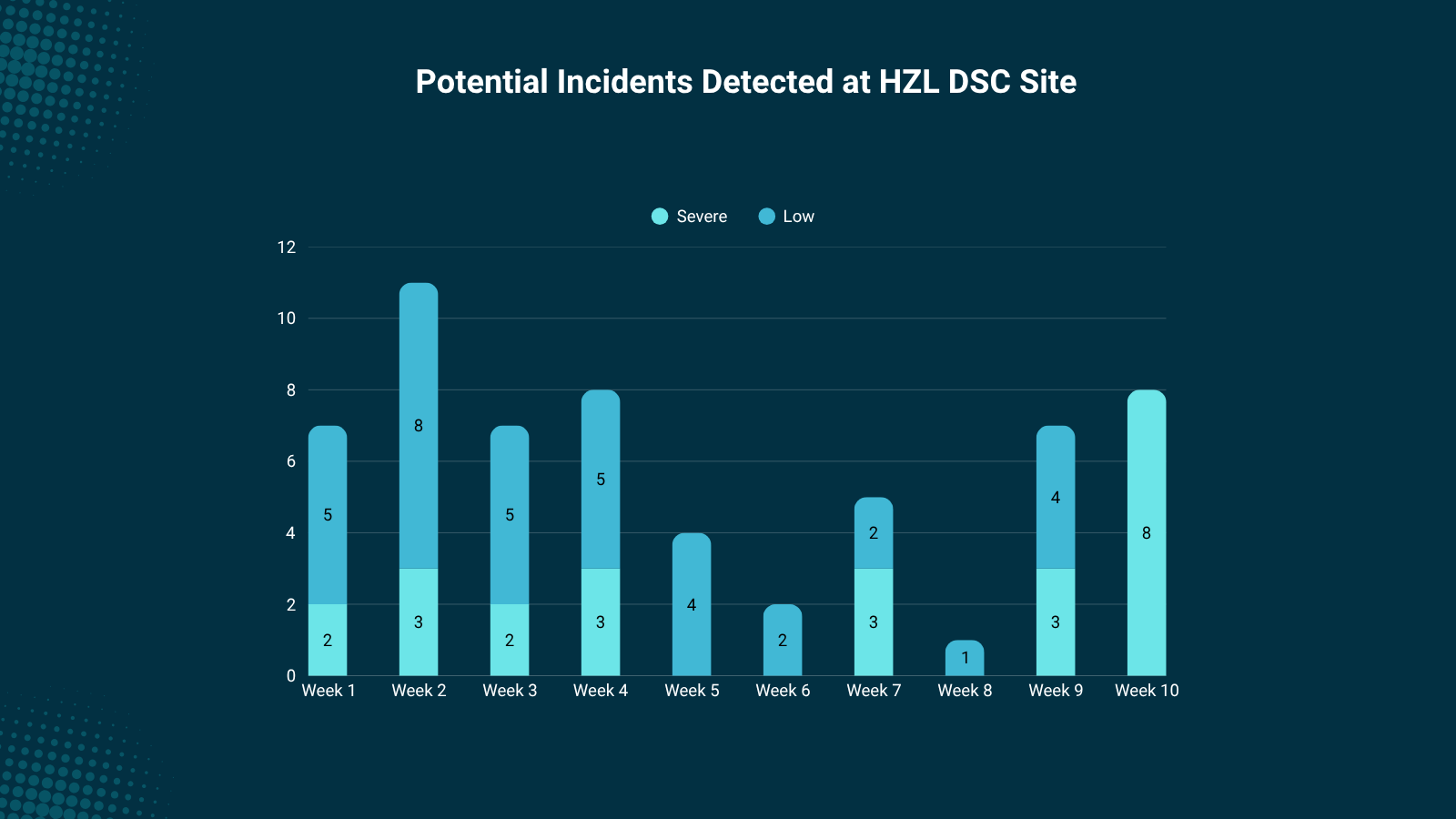

The effectiveness of the system became evident with a noticeable decline in the number of recorded accidents following its implementation. The frequency of incidents dropped to single digits, with high-severity near-miss cases approaching zero. The estimated cost savings attributed to the reduction in near-miss occurrences alone exceeded ₹8 lakh. These safety improvements also translated into enhanced logistical efficiency, generating additional annual savings of approximately ₹3.5 lakh through the reduction in travel time for trucks navigating within the industrial premises.

While financial savings and workplace safety remain core priorities for any enterprise, Hindustan Zinc Limited (HZL) is also strongly committed to minimizing its environmental footprint.

Through the deployment of the SMILE solution, peak-hour traffic congestion was reduced by 16.3%, delivering measurable environmental benefits. The decrease in idle time for vehicles contributed to a reduction in fuel consumption, which in turn led to a significant decline in carbon emissions. Specifically, CO₂ emissions were reduced by 5.5 metric tons annually due to a decrease in fuel consumption of approximately 2,000 liters. This environmental impact also reflected positively on operational costs, translating into economic savings of over ₹2 lakh per junction on an annual basis.

While Hindustan Zinc Limited’s (HZL) primary objective in deploying the SMILE system was to implement an advanced solution to mitigate traffic violations and reduce the risk of accidents within its premises, the benefits extended far beyond safety improvements. The deployment of SMILE delivered a comprehensive range of advantages—including a significant reduction in traffic infractions, enhanced operational productivity, and strengthened adherence to environmental compliance standards—offering a holistic value proposition to the organization.

Let’s walk you through the platform